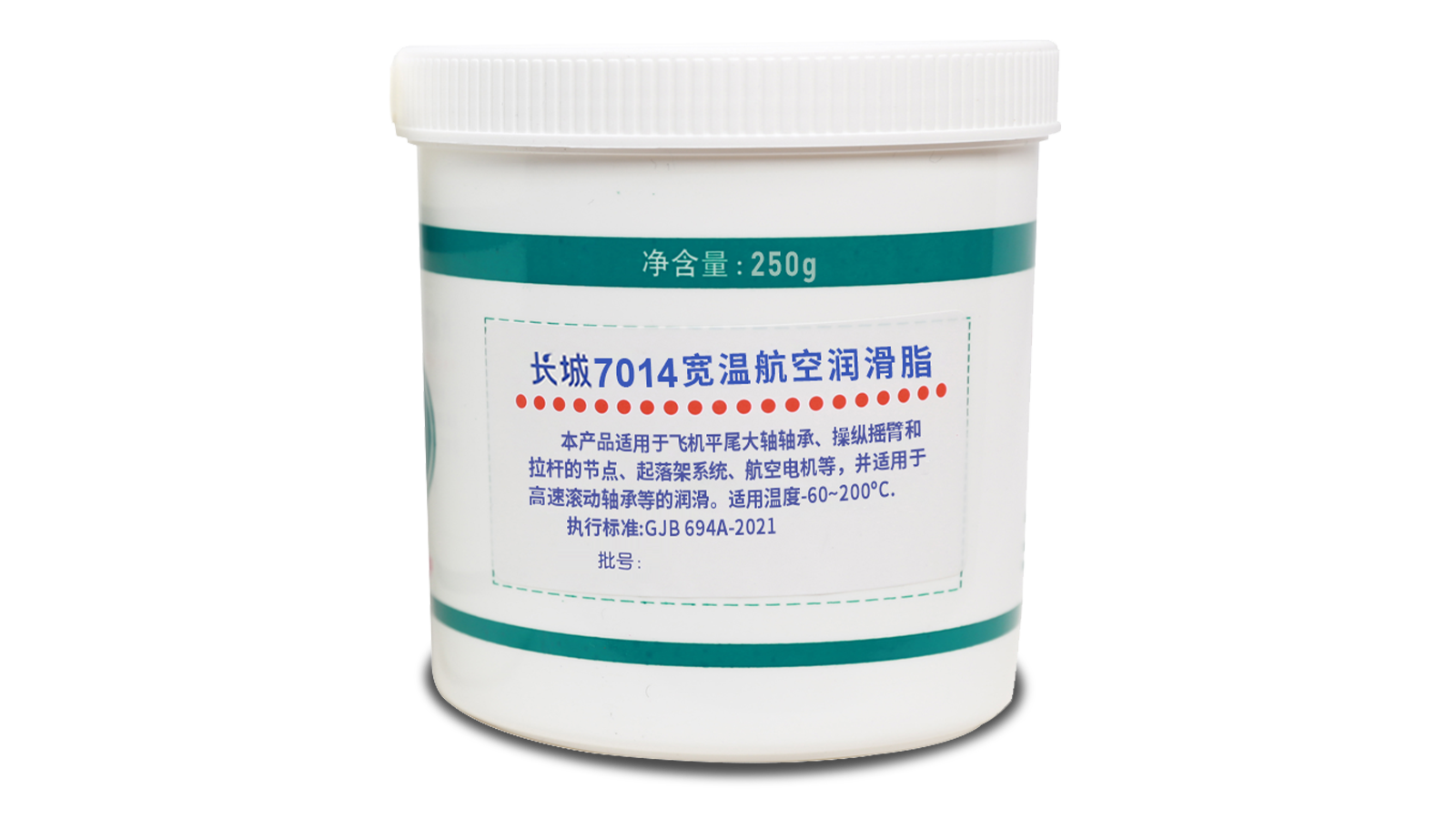

Great Wall 7014 Wide-Temperature Aviation Grease

Type: Aviation Grease

Implementation Standards: GJB 694—89

+ 8 6 1 8 6 - 2 4 9 3 - 6 7 0 8

Use: Aircraft horizontal tail bearings, controls, landing gear, wheel systems, aircraft electromechanical systems, and generators

Great Wall 7014 Wide-Temperature Aviation Grease is made from synthetic oil thickened with an organic thickener and refined with antioxidant additives.

Technical indicators

Packing Specifications

Detailed description

Overview:

Great Wall 7014 Wide-Temperature Aviation Grease is made from synthetic oil thickened with an organic thickener and refined with antioxidant additives.

Performance characteristics:

◎ Excellent high and low temperature performance, ensuring normal bearing operation over a wide temperature range

◎ Excellent lubricity, protecting bearings and reducing wear

◎ Excellent water washout resistance, suitable for lubricating bearings in humid environments

◎ Excellent mechanical and colloidal stability, preventing grease loss

◎ Excellent oxidation stability, preventing grease deterioration at high temperatures

◎ Good rubber compatibility, compatible with most rubbers

◎ Excellent storage stability, maintaining performance even after long-term storage

◎ Excellent overall performance, ensuring a long service life for high-speed bearings

Recommended:

Designed specifically for aviation lubrication, it is also suitable for a variety of civilian applications. Suitable for lubricating large bearings in aircraft horizontal tails, control and landing gear, wheel systems, aircraft electromechanical systems, generators, and various rolling bearings operating at medium speeds and over a wide temperature range in various industries, including the petrochemical and textile industries. Also suitable for lubricating electric mechanisms and general gears.

Applicable temperature range: -60°C to 200°C

Execution standard:

GJB 694—89

Technical Parameters:

| Item | 7014 Wide-Temperature Aviation Grease |

| Appearance | Black uniform ointment |

Worked Cone Penetration, 0.1mm 1/4 Cone Penetration Standard Cone Penetration | 65 269 |

Drop point, °C | 322 |

| Pressure Oil Separation, % (m/m) | 8.11 |

| Evaporation Rate (200°C, 1h), % (m/m) | 2.97 |

| Corrosion (T3 Copper Sheet, 100°C, 3h) | Qualified |

| Corrosion (T2 Copper Sheet, 100°C, 24h) | 1b |

| Water Resistance (41°C ± 1°C), % (m/m) | 145 |

Corrosion Resistance (52°C, 48h), Grade | 1 |

| Similar Viscosity (-50°C, 10s-1), Pa.s | 664 |

Four-Ball Test (1500 rpm, Room Temperature), Combined Wear Value ZMZ, N | 314 |

Fill in the requirements in 1 minute , Give you feedback within 1 hour

Usage scenarios

+ 8 6 1 8 6 - 2 4 9 3 - 6 7 0 8