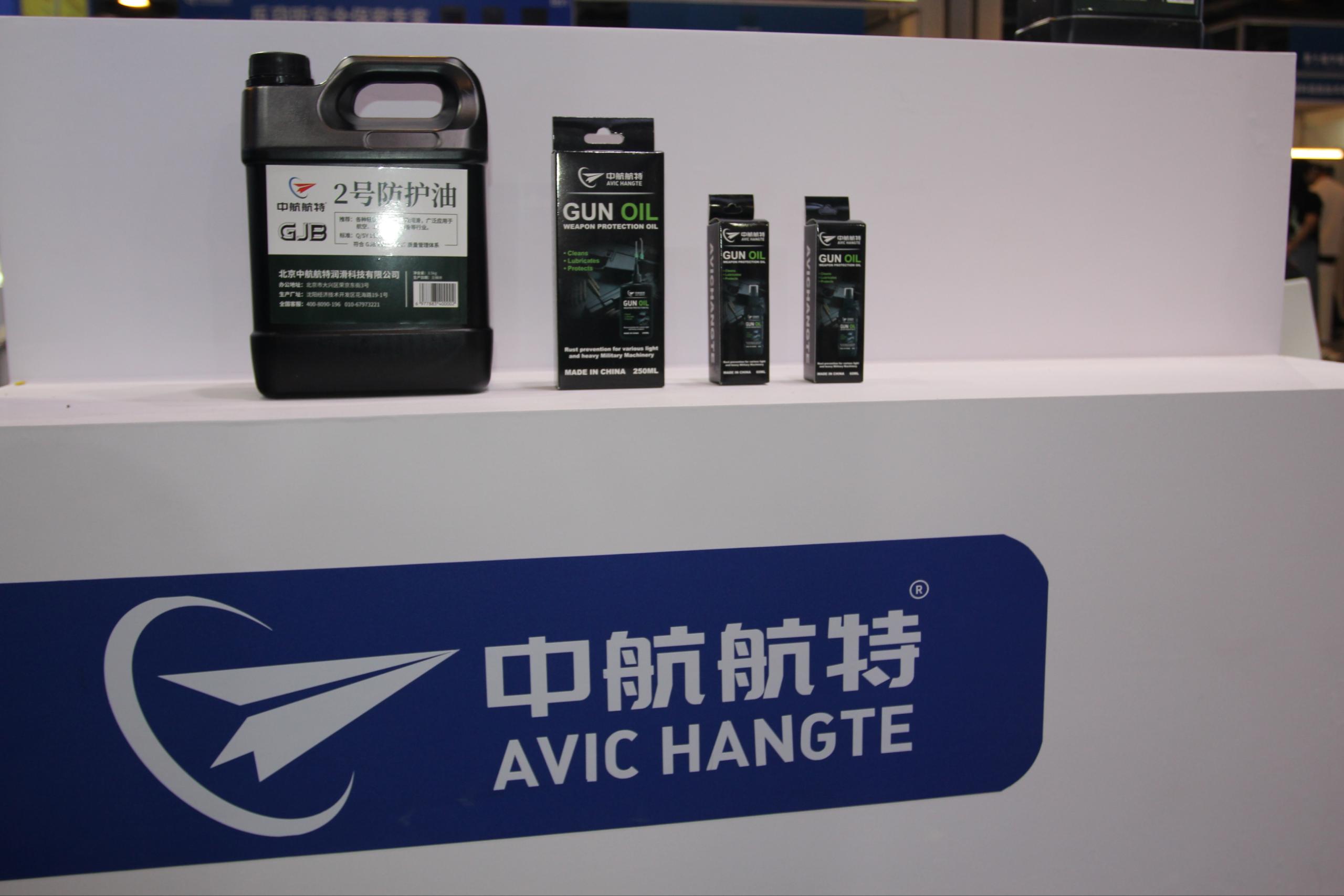

Beijing AVIC Hangte NO.2 Protective Oil

NO.2 Protective Oil Product Introduction

Product Overview:

NO.2 Protective Oil is formulated by scientifically blending refined base oil with selected additives. This product can completely replace theprotective oil that complies with the GJB2049-94 standard. It is specifically designed to meet the daily cleaning and short-term protectionneeds of light and heavy weapons in regions above -50℃ (including -50℃). At the same time, its excellent performance also makes it widely used in the inter-process rust prevention and long-term storage of various metal products.

Core features

High-efficiency rust prevention: After the solvent evaporates, a uniform and dense protective film forms on the metal surface, effectively blocking out the atmosphere, moisture, and other corrosive substances, thereby preventing metal from rusting.

Excellent performance:

Low viscosity, easy to clean: Good fluidity, facilitating coating and subsequent removal.

Transparent oil film, beautiful coating: Forms a transparent thin oil layer without affecting the appearance of the workpiece.

Low consumption and no loss: The oil film is thin and has strong adhesion, which saves the amount of oil used and reduces dripping.

Broadly applicable:

Material compatibility: Suitable for copper, aluminum and other non-ferrous metals as well as various ferrous metalsWide range of applications: Perfectly suitable for long-term storage of weapons and equipment, marine transportation equipment, offshore platform facilities, precision instruments and meters, bearings, hardware tools, springs, standard parts and various mechanical components,metal products, etc.

Application domain (usage scenario)

Military equipment: Daily cleaning and maintenance of light and heavy weapons, as well as short-term protection (-50℃ and above

temperature areas).

Marine environment: Rust prevention protection for maritime transportation vehicles (ships), marine platform equipment, and marine engineering structures. Precision equipment: Rust prevention and long-term storage procedures for high-precision components such as precision instruments,equipment, and bearings.

Industrial manufacturing: Rust prevention during the process of processing hardware tools, springs, standard components, and mechanical

parts.

Long-term storage: Long-term storage and rust prevention for various mechanical equipment and metal products.Key industries: Widely applied in industrial fields such as automobile manufacturing, shipbuilding, aerospace, mechanical processing,component production, tool manufacturing, and equipment maintenance and repair.

Usage method

Surface treatment: Ensure that the surface of the component to be sealed is clean, dry, free of oil stains and rust.

Application method: After the workpiece is cleaned with a solvent and thoroughly dried, it can be directly applied using dip coating or brush coating. It can also be used in combination with copper remover (depending on specific requirements).

Operational protection: Please wear gloves during operation to prevent contamination of the workpiece or skin contact.

Safety Warning

Flammable substances: This product is a flammable liquid. The operation and storage areas must be well-ventilated.

No Smoking: Keep away from fire sources and heat sources. Smoking and open flames are strictly prohibited at the work site.

Storage and packaging: The product should be stored in a cool and dry place, avoiding exposure to sunlight and rain.

+ 8 6 1 8 6 - 2 4 9 3 - 6 7 0 8